Advanced Materials for Precision and Performance #

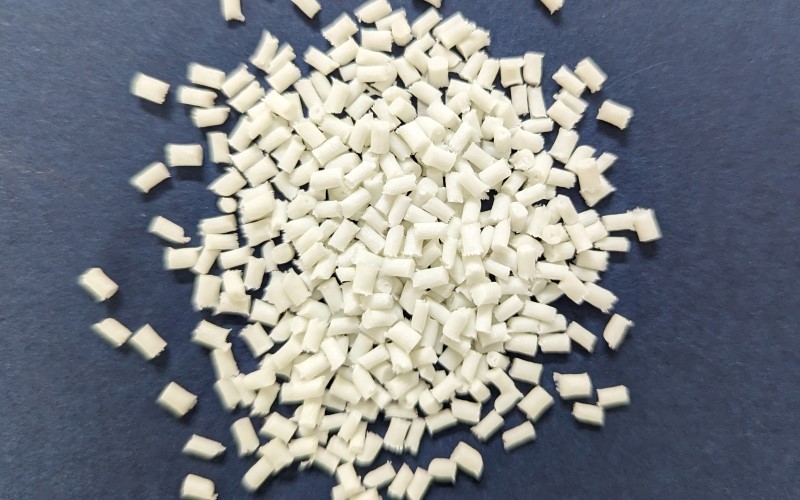

Engineering plastics, also referred to as engineering polymers, are a class of thermoplastics specifically developed for applications that require enhanced mechanical strength, dimensional stability, heat resistance, and chemical durability. Unlike commodity plastics, these materials are engineered to withstand harsh environments and maintain their integrity under stress, making them a preferred choice in precision engineering.

In many cases, engineering plastics can serve as alternatives to traditional materials such as metal, wood, or ceramics. This substitution often results in significant weight reduction and cost savings, all while maintaining or even improving performance standards. Their versatility and efficiency have made them indispensable across a range of industries, including automotive, electronics, and industrial manufacturing.

Key Engineering Plastics Offered #

ABS (Acrylonitrile Butadiene Styrene)

ABS (Acrylonitrile Butadiene Styrene)

PBT (Polybutylene Terephthalate)

PBT (Polybutylene Terephthalate)

PC (Polycarbonate)

PC (Polycarbonate)

POM (Polyoxymethylene)

POM (Polyoxymethylene)

PPE (Polyphenylene Ether)

PPE (Polyphenylene Ether)

Why Choose Engineering Plastics? #

Materials such as ABS, PBT, PC, POM, and PPE are valued for their exceptional durability, thermal stability, and resistance to chemicals. These properties make them essential in sectors like automotive, aerospace, electronics, medical devices, defense, and consumer goods. By utilizing engineering plastic pellets, manufacturers can achieve both weight reduction and cost efficiency, without compromising on reliability—even under extreme conditions.

The consistent quality and versatile processing options of these materials support efficient production and ensure long-term performance in demanding applications.