Polyamide Materials: Performance and Versatility in High-Temperature Environments #

Polyamide, widely recognized as nylon, stands out among thermoplastics for its remarkable strength, toughness, and resistance to chemicals. These attributes make polyamide a preferred material for industries requiring reliable performance under demanding conditions.

Key Polyamide Grades and Their Characteristics #

Polyamide is available in several grades, each offering a unique balance of properties such as moisture absorption, thermal stability, and dimensional accuracy. Notable grades include:

- PA46

- PA4T

- PA6T

- PA66

- PA9T

- PA10T

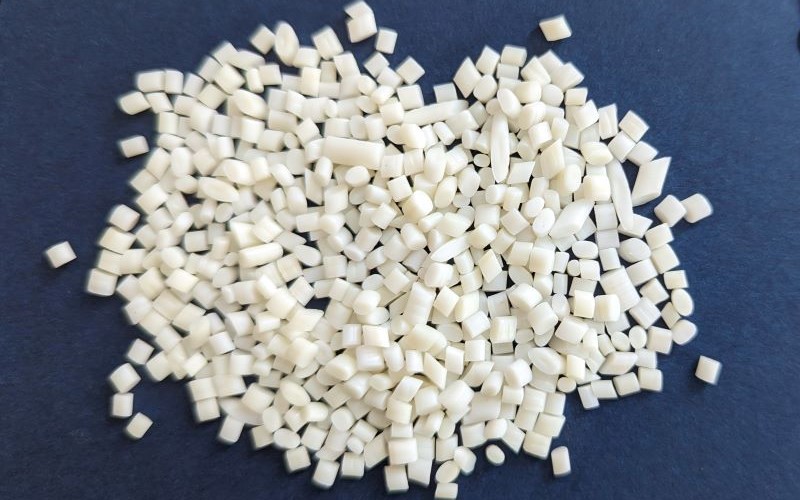

The incorporation of additives, such as glass fiber, further enhances the rigidity, impact resistance, and wear performance of these materials. Consistent melt flow and precise extrusion behavior distinguish polyamide pellets from commodity plastics, ensuring reliable results in manufacturing processes.

Applications Across Industries #

The versatility of polyamide enables its use in a wide array of sectors, including:

- Automotive

- Electrical and electronics

- Industrial machinery

- Consumer goods

Its combination of mechanical strength, chemical resistance, and thermal stability makes it suitable for high-performance components in challenging environments.

Prochase offers a comprehensive selection of polyamide pellets, including glass fiber-reinforced, flame-retardant, and custom-engineered grades. Customers benefit from technical support and flexible logistics, helping manufacturers optimize production and enhance the performance of their products.

PA6T (Polyamide 6T)

PA6T (Polyamide 6T) High-Performance PPA (PA9T & PA10T)

High-Performance PPA (PA9T & PA10T) PA46 (Nylon 46)

PA46 (Nylon 46) PA66 (Polyamide 66)

PA66 (Polyamide 66)