The Role of Thermoplastic Resins in Modern Manufacturing #

Thermoplastic resins are a fundamental class of plastic polymers known for their ability to soften when heated and solidify upon cooling. This reversible process can be repeated multiple times without altering the material’s core chemical structure, making thermoplastics highly adaptable and recyclable. By incorporating specific additives, manufacturers can tailor thermoplastics to achieve desired characteristics such as enhanced strength, flexibility, flame resistance, and UV stability, ensuring suitability for a wide array of applications.

Key Advantages and Customization #

The unique properties of thermoplastics allow for:

- Remelting and reshaping without chemical degradation

- High recyclability and sustainability

- Customization through additives for targeted performance (e.g., improved durability, resistance to chemicals, or environmental factors)

Broad Spectrum of Applications #

Thermoplastics are integral to numerous industries, including automotive, medical, consumer goods, aerospace, electronics, and sporting equipment. Their ability to maintain performance at elevated temperatures, combined with excellent chemical and impact resistance, makes them a preferred material for demanding environments. Additionally, thermoplastics offer superior electrical insulation, further expanding their utility in high-performance products and components.

Product Range at Prochase Enterprise Co., Ltd. #

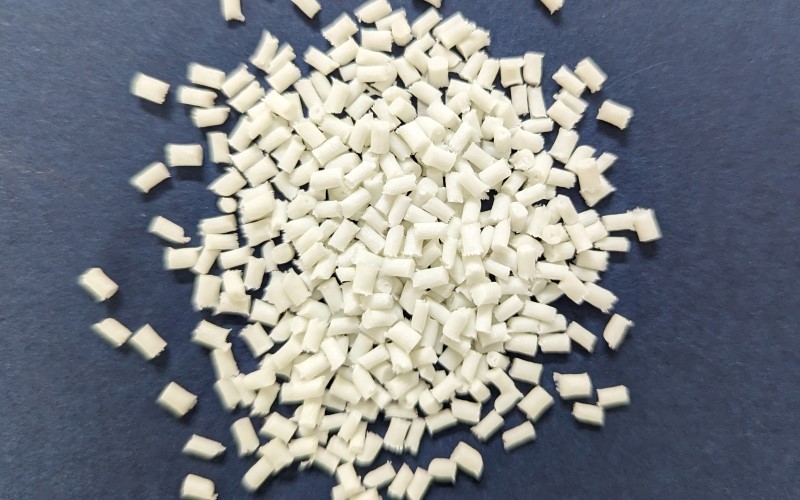

At Prochase Enterprise Co., Ltd., we provide a comprehensive selection of thermoplastic resin pellets designed to meet the diverse requirements of modern industries. Our offerings include:

- Commodity Plastics: Ideal for everyday uses such as packaging and household goods.

- Engineering Plastics: Enhanced performance materials for sectors like electronics and automotive.

- High-performance Plastics: Suitable for challenging environments, including aerospace and medical devices.

- Polyamide (PA) Pellets: Noted for their strength, wear resistance, and thermal stability, making them well-suited for heavy-duty applications.

Commitment to Quality and Service #

With over three decades of experience, Prochase is dedicated to supplying high-quality thermoplastic resin pellets that deliver consistent performance and versatility. Our customer-oriented approach ensures tailored solutions and support for innovation, helping clients realize their product development goals. Explore the full potential of thermoplastic resins with a trusted partner committed to your success.

Engineering Polymers

Engineering Polymers General Purpose Polymers

General Purpose Polymers High Performance Polymers

High Performance Polymers High Temperature Polymers

High Temperature Polymers