The Unique Advantages of Thermoplastic Elastomers #

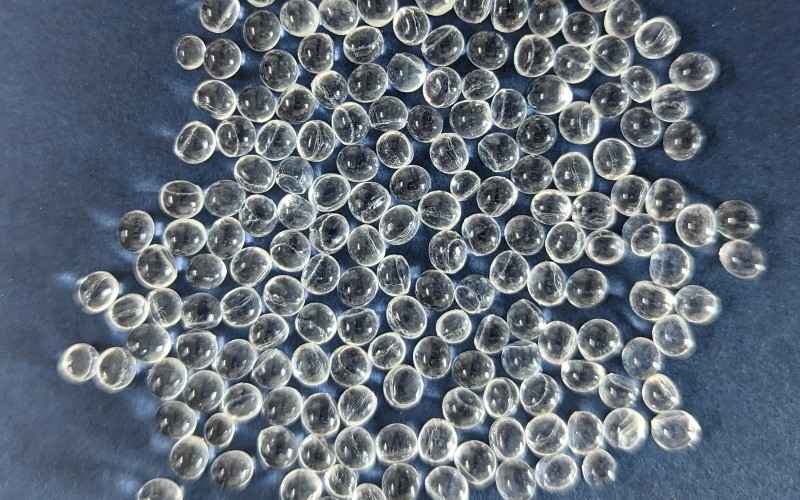

Thermoplastic Elastomers (TPEs) are a class of polymers that seamlessly blend the beneficial characteristics of both thermoplastics and elastomers. TPEs offer the processability and recyclability of thermoplastics, while also delivering the elasticity and flexibility typically associated with elastomers. Unlike traditional rubber materials, TPEs can be melted, molded, and formed into various shapes without the need for curing or vulcanization, making them highly adaptable for modern manufacturing processes.

TPEs are recognized for their design flexibility and cost efficiency. Their ability to be easily shaped and molded into diverse forms, combined with their economic advantages, has made them a preferred material in numerous industries. This versatility positions TPEs as one of the most adaptable plastics available today.

Types of Thermoplastic Elastomers #

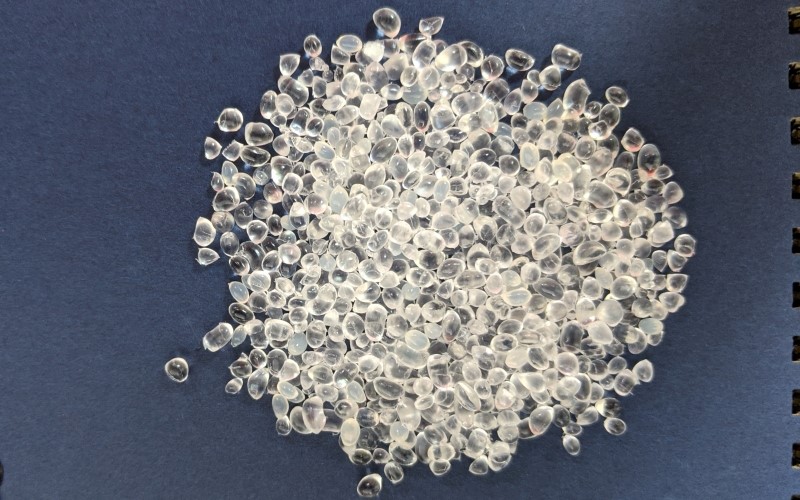

A variety of TPE materials are available, each with distinct properties suited to specific applications. The main types include:

EVA (Ethylene Vinyl Acetate)

EVA (Ethylene Vinyl Acetate)

POE (Polyolefin Elastomer)

POE (Polyolefin Elastomer)

SEBS (Styrene Ethylene Butylene Styrene)

SEBS (Styrene Ethylene Butylene Styrene)

TPEE (Thermoplastic Polyester Elastomer)

TPEE (Thermoplastic Polyester Elastomer)

TPU (Thermoplastic Polyurethanes)

TPU (Thermoplastic Polyurethanes)

- EVA (Ethylene Vinyl Acetate)

- POE (Polyolefin Elastomer)

- SEBS (Styrene Ethylene Butylene Styrene)

- TPEE (Thermoplastic Polyester Elastomer)

- TPU (Thermoplastic Polyurethanes)

Each of these materials brings unique performance characteristics, allowing for tailored solutions across a wide spectrum of product requirements.

Broad Applications Across Industries #

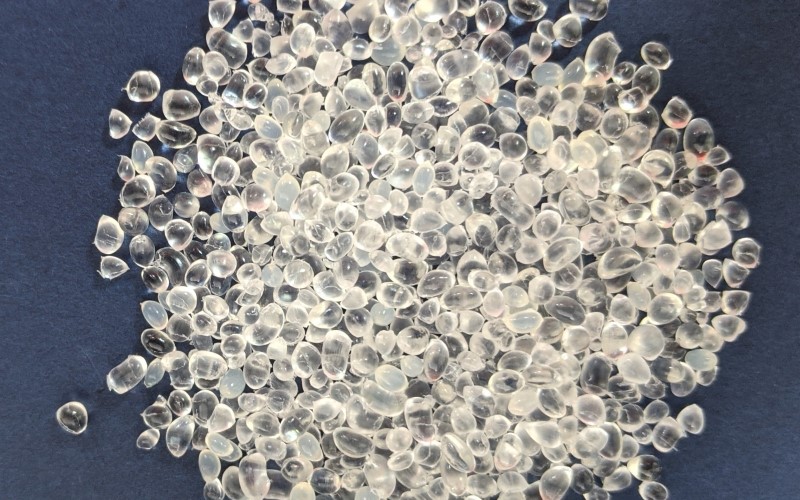

TPEs are widely adopted in various sectors due to their exceptional properties. Their weather resistance, chemical resistance, and durability make them suitable for outdoor applications. In the automotive industry, TPEs are valued for their flexibility, impact resistance, and long-term durability, making them ideal for components that require both resilience and adaptability.

The ongoing development of new TPE applications continues to expand their use. Their recyclability and versatility also contribute to their appeal as an environmentally conscious material choice in many industries.

Commitment to Quality and Service #

With extensive experience in the field, we are dedicated to supplying high-quality thermoplastic elastomers and providing attentive customer service to meet diverse application needs. Our commitment to strict quality control ensures consistent performance and reliability for every project. Explore the material categories above for more detailed information on our TPE offerings.